■ New FC-BGA Substrate

unveiled in the CES 2023

■ 1st

Significant production achieved

in last year,

Full-Scale Production will be possible in the 2nd half of this this

year

■ CEO Jeong Cheol-dong

“Enabling Global No.1 FC-BGA by Creating Differentiated Customer Value.”

LG Innotek (CEO Jeong Cheol-dong) is

accelerating the business activities in full-scale for targeting the Flip-Chip

Ball Grid Array (hereafter referred to as FC-BGA) substrate market.

LG

Innotek recently unveiled the latest FC-BGA for the first time at the ‘CES

2023’. LG Innotek’s FC-BGA is highly integrated, multi layered and large scaled.

Also, it has fine patterning and a lot of micro vias. Via means a hole connects

circuits and chips. FC-BGA of LG Innotek is known for minimizing the ‘warpage’ that

is a kind of bending phenomenon due to the heat and pressure in the

manufacturing process. It was produced by utilizing Digital Transformation(DX)

technologies, which received great interest from many companies and spectators.

LG

Innotek is continuing the efforts by accelerating the process on constructing

the new facility and capturing new customers in near future.

In January, LG

Innotek held a celebration (commemorative event for bringing in new facilities)

at the latest Gumi plant(Gumi No.4 factory) where will be mainly producing

FC-BGA. LG Innotek has been constructing the latest FC-BGA production lines in

the Gumi No.4 factory in the total gross area of approximately 220,000㎡

that was acquired in June, 2022.

After the commemoration, LG Innotek is planning

to gain speed the construction for FC-BGA. The new plant will have advanced

production system by the first half of this year and get started full-scale

production from the second half of 2023.

Especially, this outstanding

facility for FC-BGA will be constructed as the smart factory that is integrated

with the latest DX technologies including AI, robotization, unmanned system and

intellectualization, etc. When a production on a large scale is initiated at

the new place, it is expected to speed up the target for the Global FC-BGA

market; for network/modem and digital TV. Also, Development of the products for

PC/server can be feasible.

In last June, LG Innotek successfully produced

FC-BGAs for network, modem and digital TV, and products are currently being

supplied to the various companies.

The first FC-BGA production that was

utilized by the pilot line of Gumi No.2. Even LG Innotek officially entered the

FC-BGA market in February of last year, this company achieved remarkable

results in less than a year. Regarding FC-BGA

business, even if a company announces its entry into the market, it takes at

least two to three years to produce FC-BGA with excellent quality and profitable

quantity.

The key to LG Innotek reducing the period is

the innovative technology accumulated through the substrate business for the

strong trust from the existing clients.

LG

Innotek is currently No.1 in the Global market share for the substrates for Radio

Frequency System in Package (RF-SiP) and Antenna in Package (AiP). Lots of

substrates have similar manufacturing processes and technology to FC-BGA’s. Also,

LG Innotek is in the technical lead of the mobile semiconductor substrate

industry such as flip chip-chip scale package (FC-CSP) which is used in the

high-performance Application Processors (AP).

For

the development of FC-BGA, LG Innotek is actively utilizing the unequaled technologies

such as the ultra-fine circuit, high-integration array and high multi-layer

substrate matching (piling several substrate layers accurately and evenly) and

coreless (removing the core layer on the semiconductor substrate) technologies during

50 years in the industrial fields.

Moreover,

the trust with the existing customers accumulated through long partnership in

the communication/semiconductor/household appliance fields contributed greatly

to reducing the output period. FC-BGA is a type of semiconductor substrate, and

mostly compatible to the major clients who are taking the substrates for RF-SiP

and AiP.

In addition, the

extensive efforts by LG Innotek, such as the quick response to qualified

production by utilizing the existing pilot line in Gumi No.2 factory, strict

supply chain management and quick warehousing of major equipment, etc.

contributed to cutting down the producing period.

Based on the construction of the new plant for

FC-BGA and experience of first big success, LG Innotek is actively proceeding

with the promotions for tentative customers. Starting from the first investment

of USD 336 million (KRW 413 billion) in last year, LG Innotek plans to continue

investing in FC-BGA.

CEO Jeong Cheol-dong stated that “Since LG

Innotek has been leading the substrate material market with its world-class

technology, it will be able to develop our FC-BGA business into a Global No.1”.

According to the Fuji Chimera Research Institute, the Global FC-BGA

substrate market size is estimated to show annual average growth rate of

approximately 9% from USD 8 billion (KRW 9.984 trillion) in 2022 to USD 16.4

billion (KRW 20.4672 trillion) by 2030.

CEO

Jeong Cheol-dong (middle) participating in the tool-in ceremony held at Gumi

No.4 factory, there are advanced facilities for producing FC-BGA.

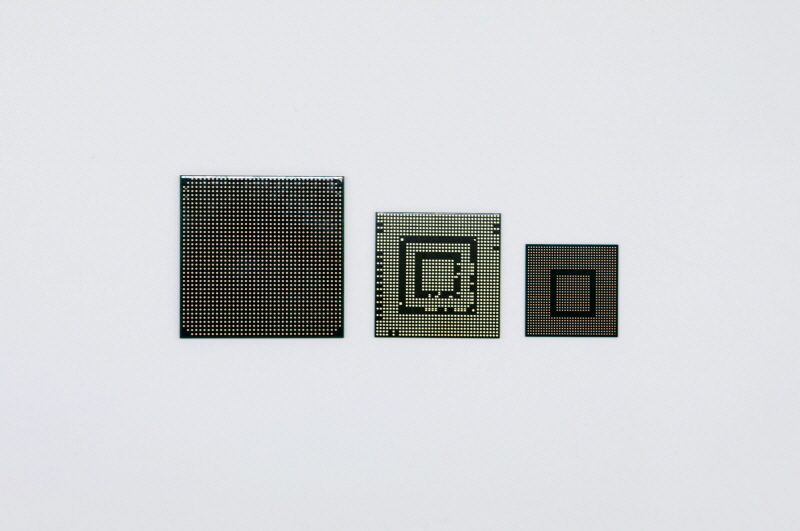

LG

Innotek’s FC-BGAs.