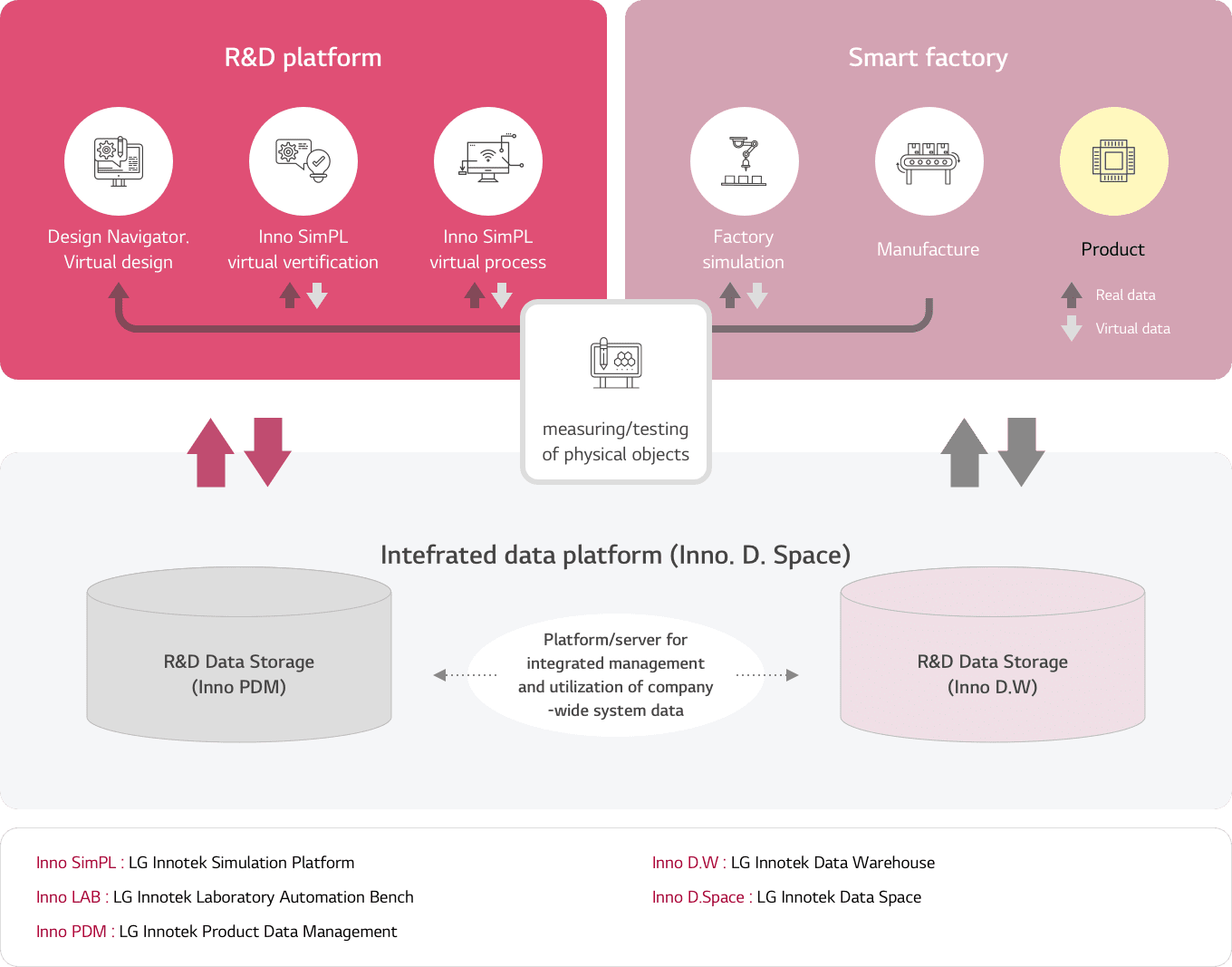

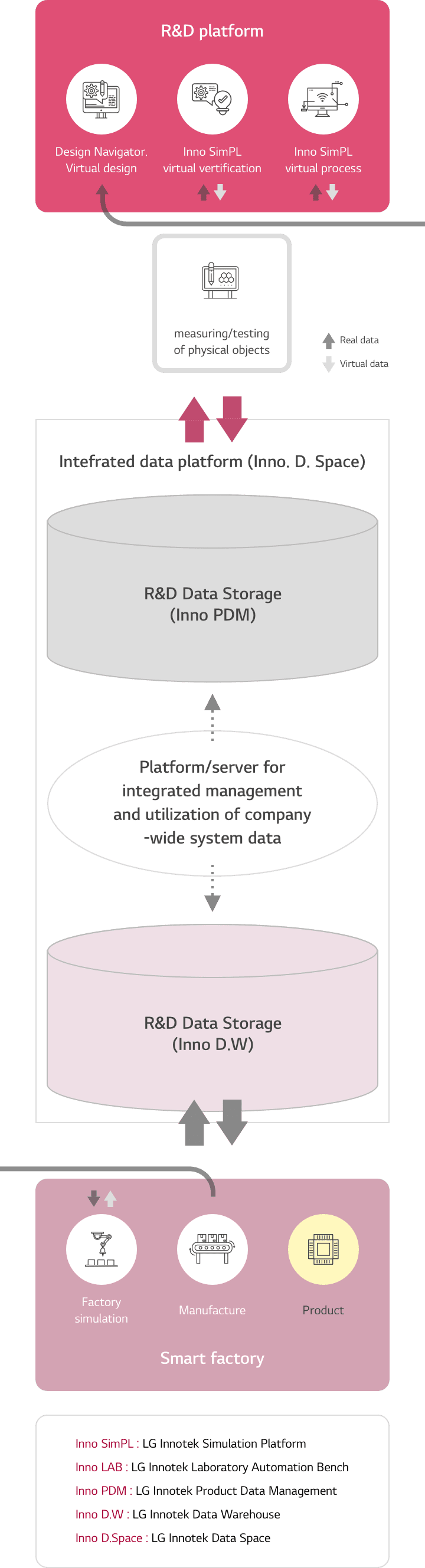

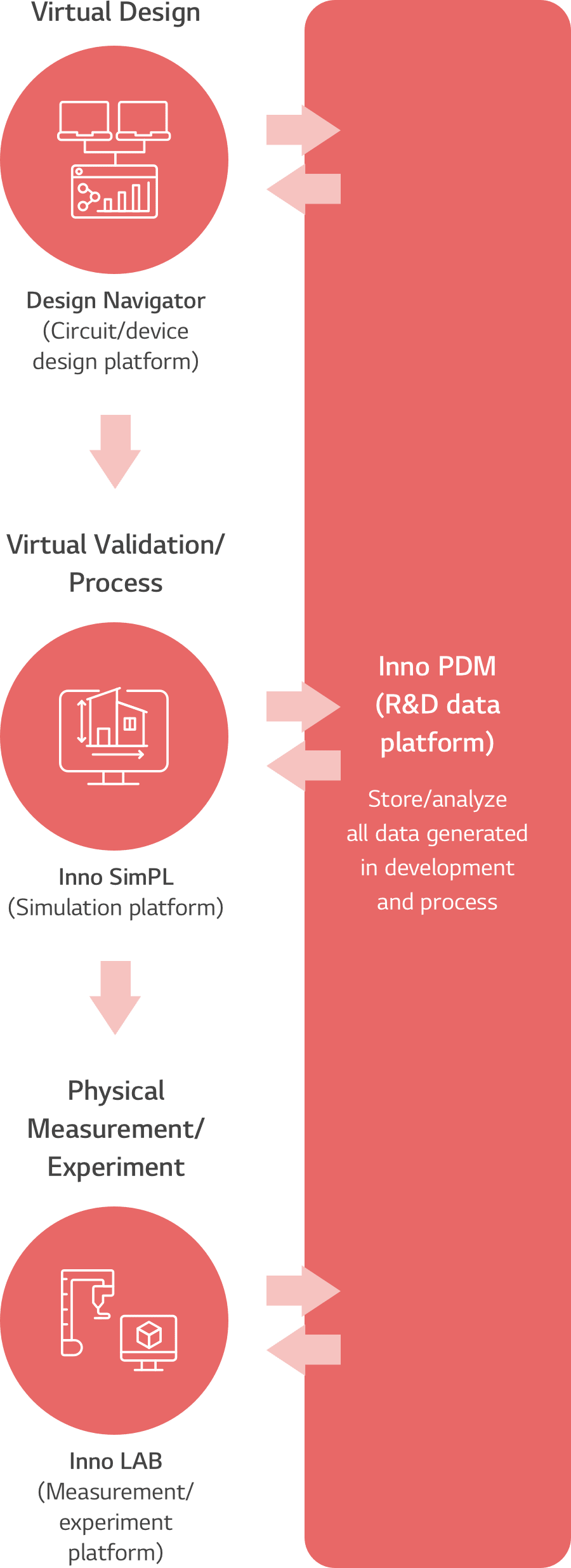

1 Virtual Design (Design Navigator): With Design Navigator, a virtual design platform, you can automate circuit or mechanism design of parts to shorten development lead times and upgrade design quality.

2 Virtual Validation/Process (Inno SimPL): In Inno SimPL, a platform that can automatically conduct simulations, virtual verification is performed based on virtual design, and the defect rate of core processes can be predicted and improved through virtual processes in advance.

3 Physical Measurement/Experiment (InnoLAB): Inno LAB is a platform that collects data generated by measuring real parts from development to process stages and integrates them to be used in the virtual design/verification/process of the next product. This integrated data helps to improve prediction accuracy before designing and producing other products, and helps maintain performance.

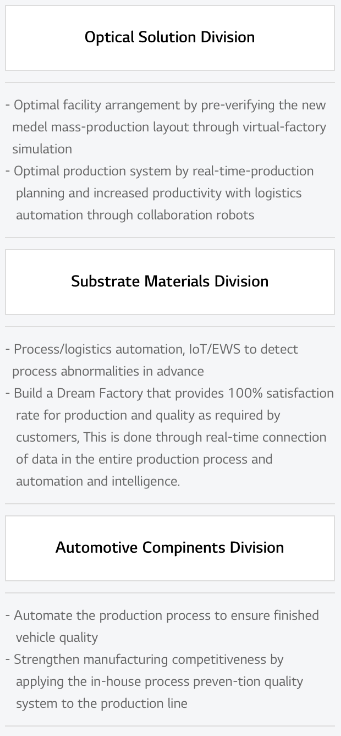

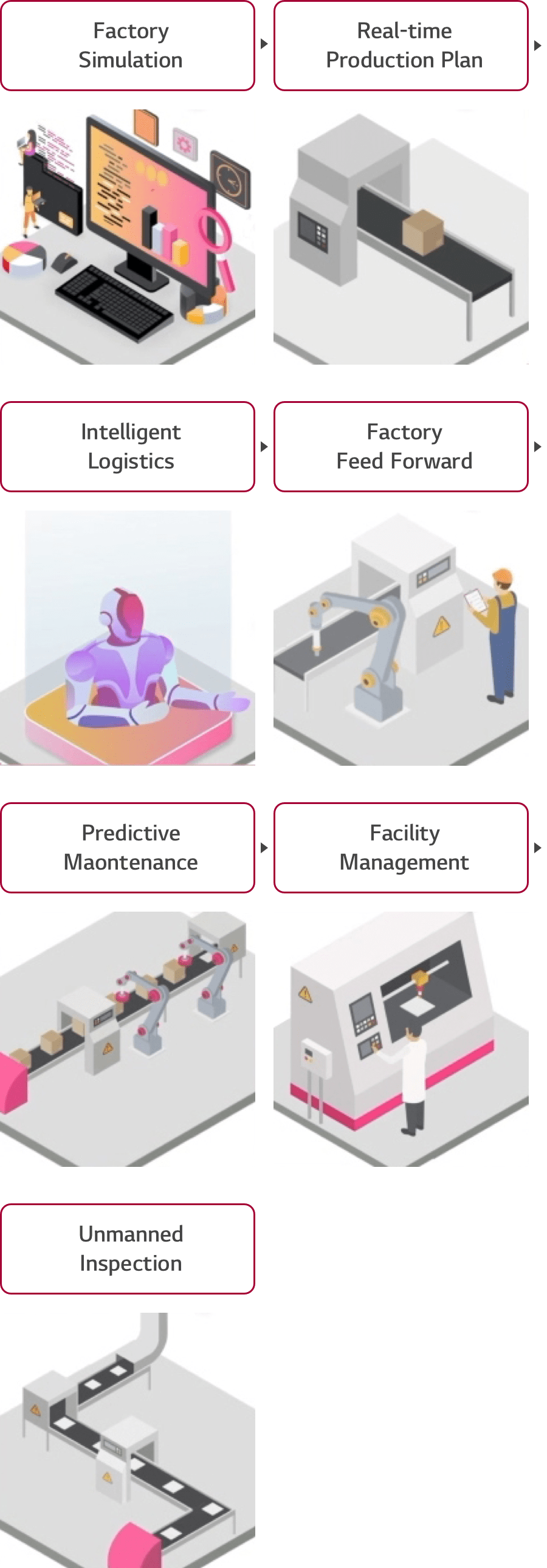

LG Innotek’s Smart Factory Focus Areas

LG Innotek's smart factory is being developed to respond to the characteristics of each business sector, ranging from optics, substrates, and electronics. With the initiation of smart-solution applications, the entire production process is integrated with data, and the efficiency of the production line is advanced by using AI for inspection, control, and judgment. In addition, to strengthen ESG activities, the use of renewable energy in all production areas, utility greenhouse gas reduction, fuel conversion, and energy efficiency/process improvement activities are underway. Accordingly, LG Innotek plans to convert all electricity used at its production sites to renewable energy by 2030, and aims to achieve carbon neutrality by 2040.

LG Innotek Smart Factory Processes

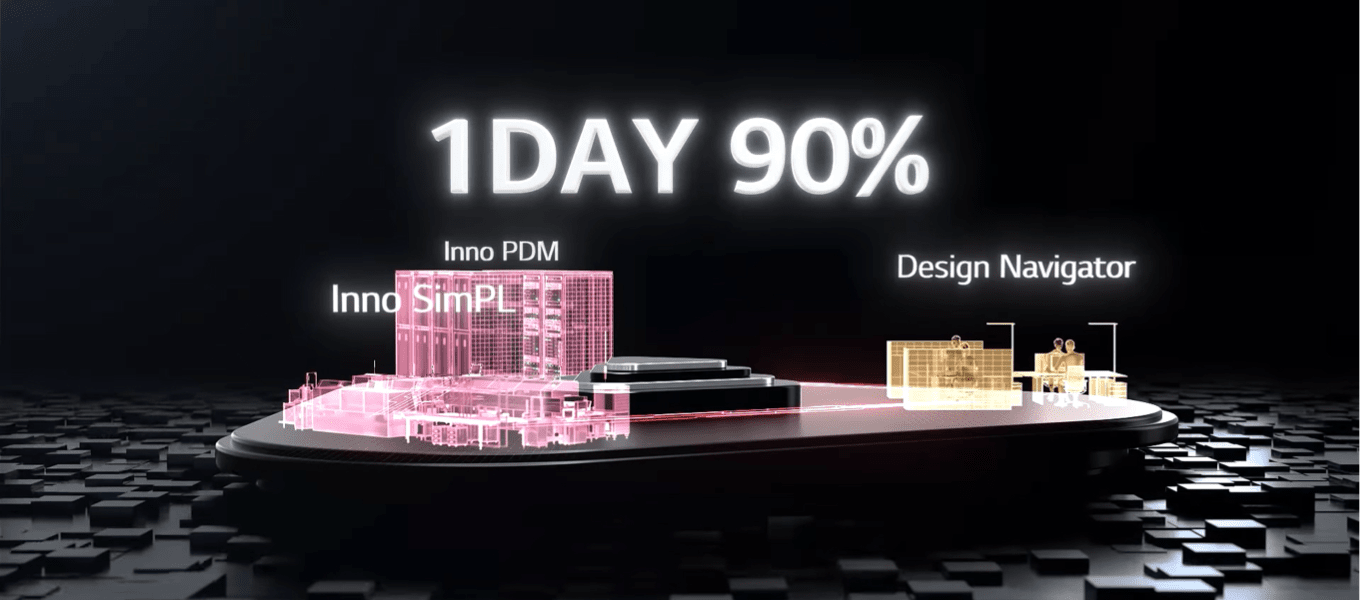

Point of Difference

Goal of 90% in 1 Day

With the goal of 90% per day, LG Innotek intends to realize a digital twin through data-based virtual design, virtual verification, and virtual process and measurement experiment data connection. The goal is to perform design verification and failure prediction simulation of major processes with 90% accuracy within one day. LG Innotek aims to significantly shorten the lead time of product development for customers by predicting and responding to defects that may occur in the customer's process as well as the entire process from development and mass production of its products, which will lead to a stronger customer market competitiveness.

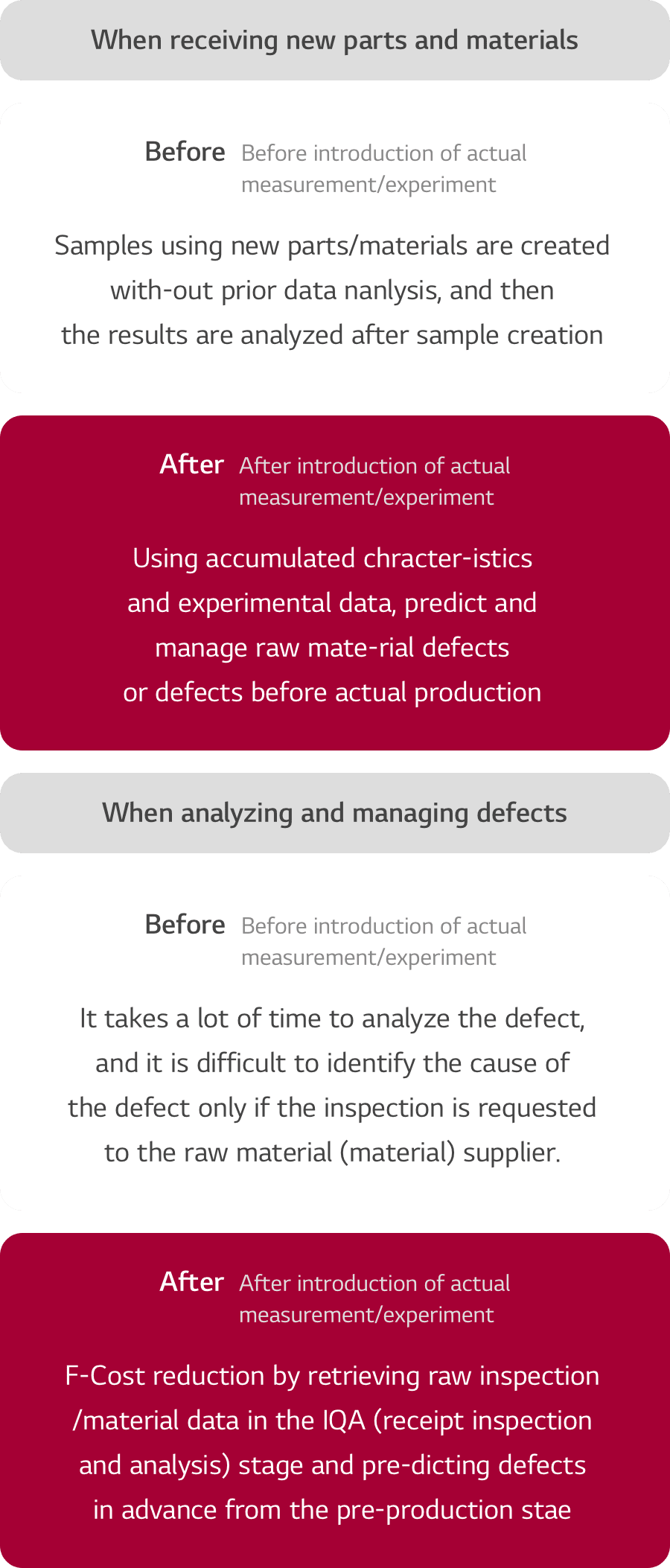

Integrate “physical measurement/experiment” data from R&D to production

LG Innotek utilizes measurement/experimental data of various real-world products (samples, final products, etc.) in all stages from product design to production at the time of designing/production of other products in the future. This is to identify defects in raw materials or process issues in advance to build a specialized platform (Inno LAB). All data(conditions and results of raw materials, temperature, angle, etc.) produced from various real-world objects are automatically collected, stored, and connected back to the virtual development stage, thereby improving prediction accuracy and performance.

Pursuing a smart, autonomously operated factory that detects, judges and

implements itself

Integration between R&D Platform and Smart Factory

By seamlessly connecting/using data, it becomes possible to analyze/respond to defects in connection with development even after mass production. When a defect occurs in the process, it is possible to respond faster and more accurately through virtual simulation based on real and existing accumulated data, than it is by only using the design of experiments (DOE) method in the field. In addition, this result data is be reflected in advance when designing the next product in order to minimize or remove the chance of recurrence of the same defect.

Factory simulation

LG Innotek has completed digital twin-based simulations for all lines in the company’s plants, and the completed values are secured in the ‘Digital Factory Library’. Based on the information such as production volume and lead time stored in this library, the process for each line is rationalized, and it is also used when building a new line. As a result, when expanding a factory line or constructing a new one, the procedure that was previously reviewed manually by humans disappears and the analysis/verification time for each process can be shortened.

.png)

.png )

.png )

.png)

.png)

.png)