Optics Solution

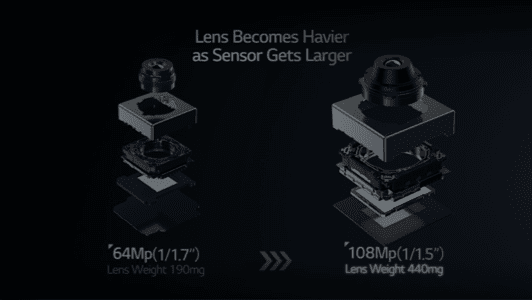

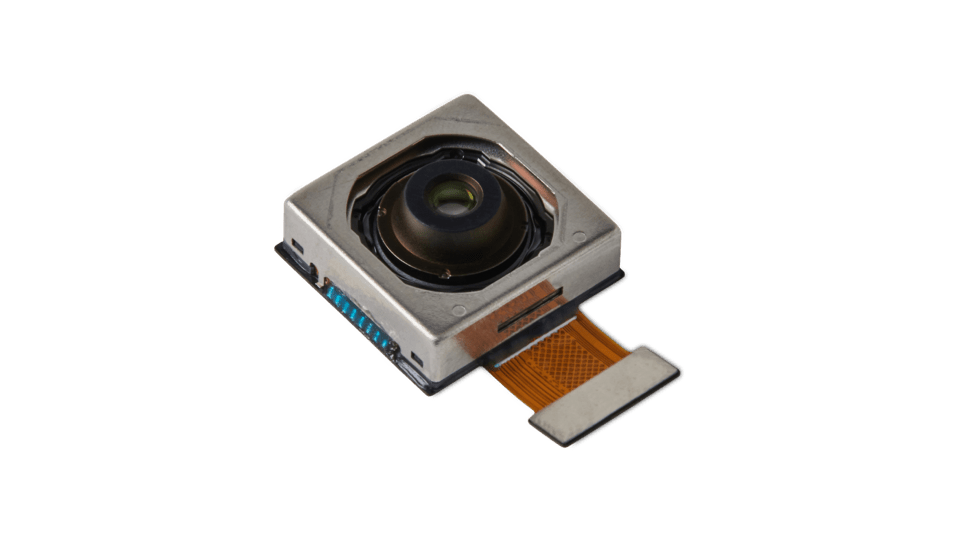

Camera Module

High-performance/multi-function camera module that maximizes user convenience through various functions such as high-definition shooting, auto focus, image stabilization, wide-angle shooting, and high-magnification optical zoom

3D Sensing Module

A module that extracts a three-dimensional depth map by measuring the distance from the photographer to a specific object or point

Actuator

A driving part that performs the AF for precise focusing in the camera module, OIS for correcting shake, and the zoom function for magnified photography