LG Innotek (CEO Ung-Beom Lee) succeeded in mass production of UV LED using large-size 6-inch wafers for the first time in the world.

LG Innotek has overcome limits of the previous UV LED products by applying to the 6-inch wafer a vertical LED chip technology the Company developed on its own to enhance productivity and optical power of UV LED.

LG Innotek’s 6-inch wafer-based UV LED can increase productivity by about 28 percent compared with those based on 2-inch-based wafers.

■ Lays foundation to gain upper hand in UV LED market segment, after LEDs for displays and lighting segments

Analysts say that with the successful mass production of 6-inch wafer-based UV LED, LG Innotek has laid foundation to gain the upper hand in the UV LED market, which has emerged as a new market.

According to industry sources, the UV LED market is projected to make exponential growth at an annual average rate of 43 percent from about 47 billion won last year to 280 billion won in 2017. At the same time, the UV LED penetration ratio in the conventional UV Lamp market is expected to grow from 12.7 percent last year to 34.7 percent in 2017.

Ultraviolet means shorter wavelength light that measures about 100 to 400 nanometers, shorter than that of visible rays. Depending on wavelength band, UV provides such functions as sterilization, purification, and Curing (consolidation of liquid state material). It also has diverse areas of applications, including medicine, surface coating and printing. In the future, its applications will likely further expand to include the environment industry, including purification of waste water.

UV LED is an ultraviolet ray-emitting device, and is a lighting source that uses LED, a semiconductor compound, in lieu of mercury lamp. In the course of LED production, UV LED can be designed to only emit efficacious wavelength required for respective uses, including medicine, home appliances and Curing of coating.

On the other hand, UV LED poses a very high technology barrier due to difficulties in forming photic layer that presents ultraviolet rays. High price and low optical power of UV LED due to technological barriers previously posed obstacles to the expansion of its market.

LG Innotek has secured price competitiveness by increasing productivity of LED production by using large-size 6-inch wafers in lieu of conventional 2-inch or 4-inch wafers.

For LED production, the larger the wafer, the more LED chips can be produced at once. LED is produced in the form of LED chips and packages by piling up semiconductor compound on the wafer and thus forming light-emitting layer, before chopping the wafer into fine pieces.

LG Innotek also maximized the optical power of UV LED by using vertical LED chip technology. As for vertical LED, UV emission used to be interrupted due to the thickness of GaN, which formulates the light-emitting layer. LG Innotek minimized the thickness of GaN layer by developing a vertical LED chip design technology.

An official at LG Innotek said, “Capability in UV LED technology can be considered a barometer that determines a company’s capacity in LED technology, going beyond its marketability,” adding, “The achievement demonstrates that a Korean company has reached the top level in the world.”

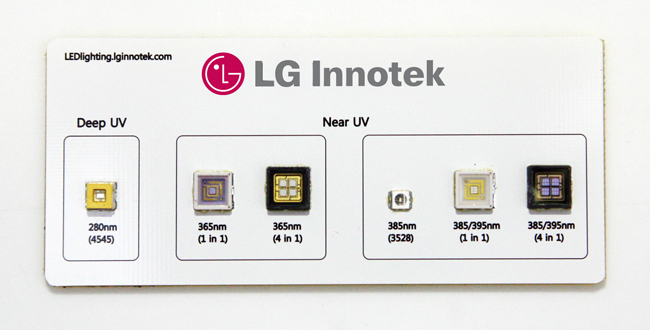

■ Company secures UV LED product lineups ranging from products for general industrial use, sterilization function-based medicine, and those for environment industry

LG Innotek plans to step up efforts to expand market by banking on products optimized for respective use according to UV wavelength, ranging from 365nm, 385nm, 395nm, and 405nm UV LED for general industrial use, to 280nm UV LED applicable for sterilization and medicine.

The 365 to 405nm-class UV LED has far-reaching applications ranging from general industrial use such as high-glossy coating and printing to hardening after bonding of electronic devices, including TV and mobile phones.

Notably, LG Innotek’s 385nm 4in1 UV LED package is a high-performance product presenting the maximum optical power of 2,600 mW. Because this package can reduce the number of packages required per UV device, it comes in handy for reducing the size of finished products. The 4 in 1 UV LED is comprised of four LED chips in a single LED package.

LG Innotek’s 280nm UV LED offers efficacy in sterilization and purification, and thus can have diverse applications ranging from electronic appliances such as refrigerators and water purifiers to medical equipment. Notably, unlike conventional UV lamps, the UV LED does not use mercury, a heavy metal, and thus poses little risk of environmental pollution, and is environmentally friendly due to its long lifespan. As such, it will likely be applied in medicine and environmental purification without generating sense of resistance among users.

An official at LG Innotek said, “By applying large-size wafers to specialty LED including UV LED, after the LED for display backlight unit (BLU), for which 6-inch wafers were applied earlier, the Company has secured global competitiveness in all products,” adding, “Through ceaseless efforts to develop technology, we will introduce innovative products that exceed customers’ expectations.”

###

[Photo caption]

Photo 1 – 2) 6-inch Epi wafer (left), on which light-emitting layer has been formulated by LG Innotek by applying a 6-inch wafer for the first time in the world, and UV LED package products (right)

Photo 3) 6-inch wafer-based UV LED package products developed by LG Innotek